Site Search

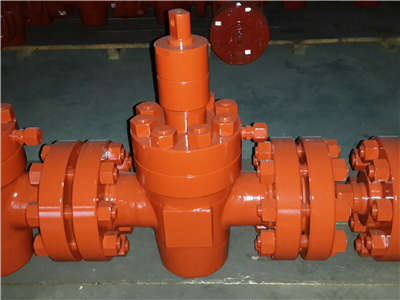

Structural characteristics and working principle of high pressure flat gate valve

1. Adopt floating valve seat, bidirectional opening and closing, reliable sealing and flexible opening and closing.

2. Diversion hole is set at the lower part of the gate, which can guide accurately. The sealing parts are sprayed with welding hard alloy at the same time, which is corrosion-resistant.

3. The bearing capacity of valve body is high and the channel is straight. When the gate is fully opened, it is similar to the straight pipe connected with the gate diversion hole, and the flow resistance is very small. The valve stem adopts composite packing and multiple seals, which has reliable sealing and small friction.

4. Close the valve and turn the hand wheel clockwise to lower the gate. Due to the mass pressure of the interface, the sealing seat at the inlet end is pushed to the gate. A large sealing pressure is formed to form a seal. At the same time, press the pressure head on the seal seat facing the outlet end, which becomes a double seal.

5. Due to the use of double sealing, it can not affect the work of the pipeline and replace the worn parts. This is an important feature of our products superior to those of the same trade at home and abroad.

6. When opening the louver, rotate the hand wheel anticlockwise to move the shutter upward. The guide hole and the guide slot hole are connected. With the rise of the gate, the through hole gradually becomes larger. When it reaches a certain position, the diversion hole overlaps with the passage hole, and then it is fully opened.