Site Search

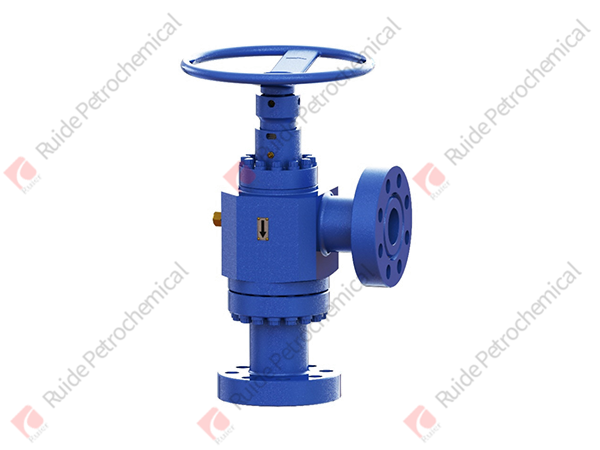

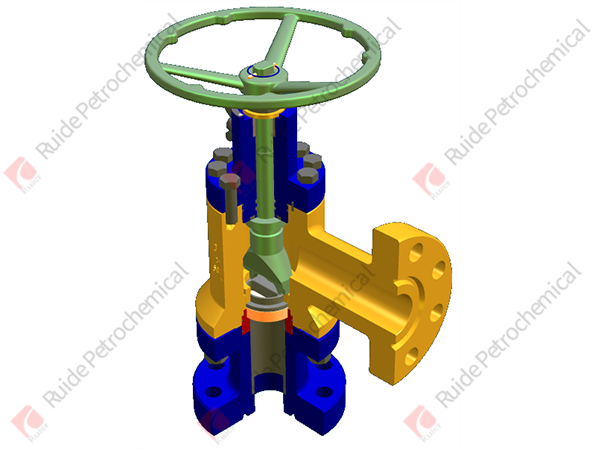

Orifice plate choke valve

The orifice plate choke valve uses a rotary fork to drive the valve seat assembly. Generally, it only needs to rotate the fork 90 ° or 180 ° to realize the valve opening and closing. Both ends of the fork are pre tightened to improve the fork stiffness, reduce its vibration, and make the fork run smoothly and safely. With the hydraulic, pneumatic and electric drive devices, the orifice plate throttle valve can achieve more accurate adjustment, so the orifice plate throttle valve is widely used.

Basic parameters

Nominal diameter: 2-1 / 16 "~ 4-1 / 16"

Working pressure: 2000psi ~ 15000psi

Temperature: – 75 ° f ~ + 250 ° f (– 60 ° C ~ + 121 ° C)

Main materials: AA, BB, CC, DD, EE, FF, HH

Specification level: psl1-3g

Performance level: pr1-2

Nozzle specification: 1 "~ 2"