Site Search

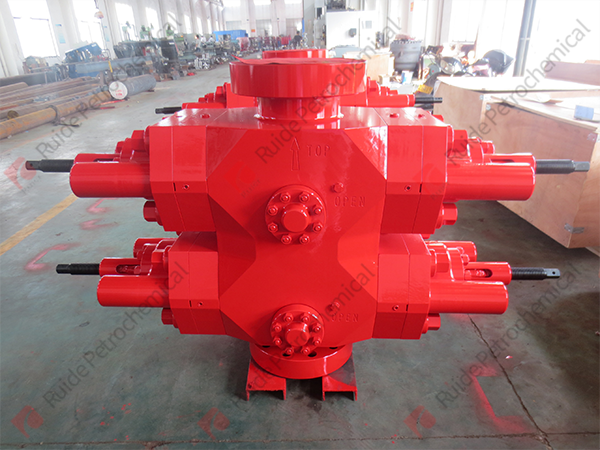

Double ram BOP

The ram BOP, shell and main parts are forged. The ram chamber of the shell is elliptical on the longitudinal section of the vertical piston rod. The ram is opened and closed by the piston rod pushed by the hydraulic cylinder. The movement of the side door is linear, and the action of the side door is controlled by two hydraulic cylinders. An automatic sand cleaning structure is designed on the shell. The ram is designed with automatic centering structure. Two outlets are designed on the side of the shell to connect the kill and choke manifold for mud circulation, throttling and blowout, well killing, well flushing and other special operations. The cylinder body is designed with a relief port, which can release the pressure and protect the device when the pressure is too high. The secondary sealing device is designed on the middle flange. In case of emergency, it is found that there is liquid leakage at the observation port, which can be used for emergency grease injection.

Technical features

The shut in action is rapid and can be shut in within 3 ~ 8 s.

It is easy to operate and can be controlled remotely.

The cavity is of oblong cross-section, with uniform force and strong bearing capacity.

The side door assembly can realize the hydraulic linear switch, which is convenient to replace the ram and maintain on site.

The radial floating seal is used to replace the traditional face seal.

The ram shaft seal adopts three seals, which are reliable.

The ram rubber core adopts self-contained seal and has a large rubber reserve.

The function is easy to expand, and can be equipped with shear booster device, hydraulic locking device, etc.

Basic parameters

Nominal size: 7-1 / 16 "~ 21-1 / 4"

Working pressure: 2000psi ~ 20000psi