Site Search

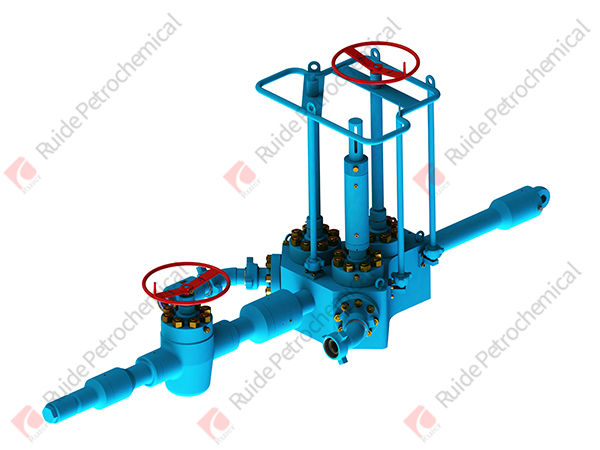

Ground rotation test tree

The ground rotating test tree (flow control head) is the main equipment for controlling oil and gas wells and running cables;

1. Equipment such as blowout preventer and blowout preventer for upper connection of cable and steel wire operation;

2. The lower part is connected with drill pipe or oil pipe;

3. The flow head is usually equipped with a rotary nipple to rotate the lower string, such as setting packer;

4. Hang the lifting nipple with the lifting ring of the drilling crew to hang the control head;

5. There are four gate valves arranged in cross shape;

6. The main valve is a manual valve at the lower part, which is used to isolate the well and surface flow;

7. The suction valve is a manual valve located at the upper part, which is used to run the cable tools into the wellbore;

8. The flow wing valve is a hydraulically controlled fault free normally closed valve, which is pressurized and opened through the control panel to release pressure and shut in the well quickly in case of emergency;

9. The kill wing valve is a manual valve, which is connected with the pump truck through a single flow valve during the test, and is used for well killing in case of emergency;

technical parameter

Working environment: sulfur proof

Pressure rating: 2000psi ~ 15000psi

Maximum working temperature: 121 ℃

Minimum operating temperature: - 29 ℃

Type of valve: gate valve

Valve configuration: suction valve 3-1 / 16 ″

Manual valve, kill wing valve 3-1 / 16 ″

Manual valve, flow wing valve 3-1 / 16 ″

Hydraulic control valve, main valve 3-1 / 16 "manual valve

Upper buckle: 5-3 / 4 "- 4stub acme box

Lower buckle: 3-1 / 2 ″ if pin

Connecting buckle of kill wing: 3 ″ Fig. 1502 hammer union thread

Connecting buckle of flow wing: 3 ″ Fig. 1502 hammer union wingut

Sealing type of pipeline connection: FR 58 / 90 (Anson superseal)

Maximum tension: 182 tons at maximum tension

Weight: 3000 kgs / 3.00 tons

Dimensions: 168.5 inches long, 54.5 inches wide and 66.5 inches high (excluding rotating or lifting joints)