Site Search

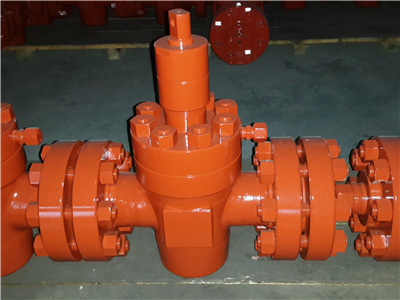

Manufacturer of high pressure flat gate valve

Maintenance method of high pressure flat gate valve

(1) Check the valve material of high pressure flat gate valve, and do not misuse it. The material of valve replacement parts shall be tested by metallographic spectrum. The material of valve shall be approved by metallographic inspector and recorded.

(2) Clean and inspect the high pressure flat gate valve for sand holes, cracks and corrosion. In case of defects, repair welding can be used.

(3) The sealing surface of high pressure flat gate valve shall be tested with red lead powder. The contact point should reach 80%. If the contact point is less than 80%, grinding is required. The concave surface and deep groove of the joint surface shall be treated.

(4) The bending and ovality of the valve rod of the high-pressure flat gate valve shall meet the requirements, and the thread and nut of the valve rod of the high-pressure flat gate valve shall meet the requirements.

(5) Check whether the upper and lower clamping plates of the high-pressure flat gate valve have cracks, welding, erosion, deformation and serious damage, whether the valve adjustment is flexible, whether the thread of the locking nut is well matched, and replace if there is any defect.

(6) Clean and inspect bearings with kerosene. There is no crack in the bearing, the ball is flexible and complete, and the butterfly fold pad has no crack or deformation.

(7) Clean the valve body, cover, packing chamber, Bush, pressure ring, fixed ring, packing gland, bolts and various parts of high pressure flat gate valve.

(8) Measure the clearance of each part of high pressure flat gate valve.